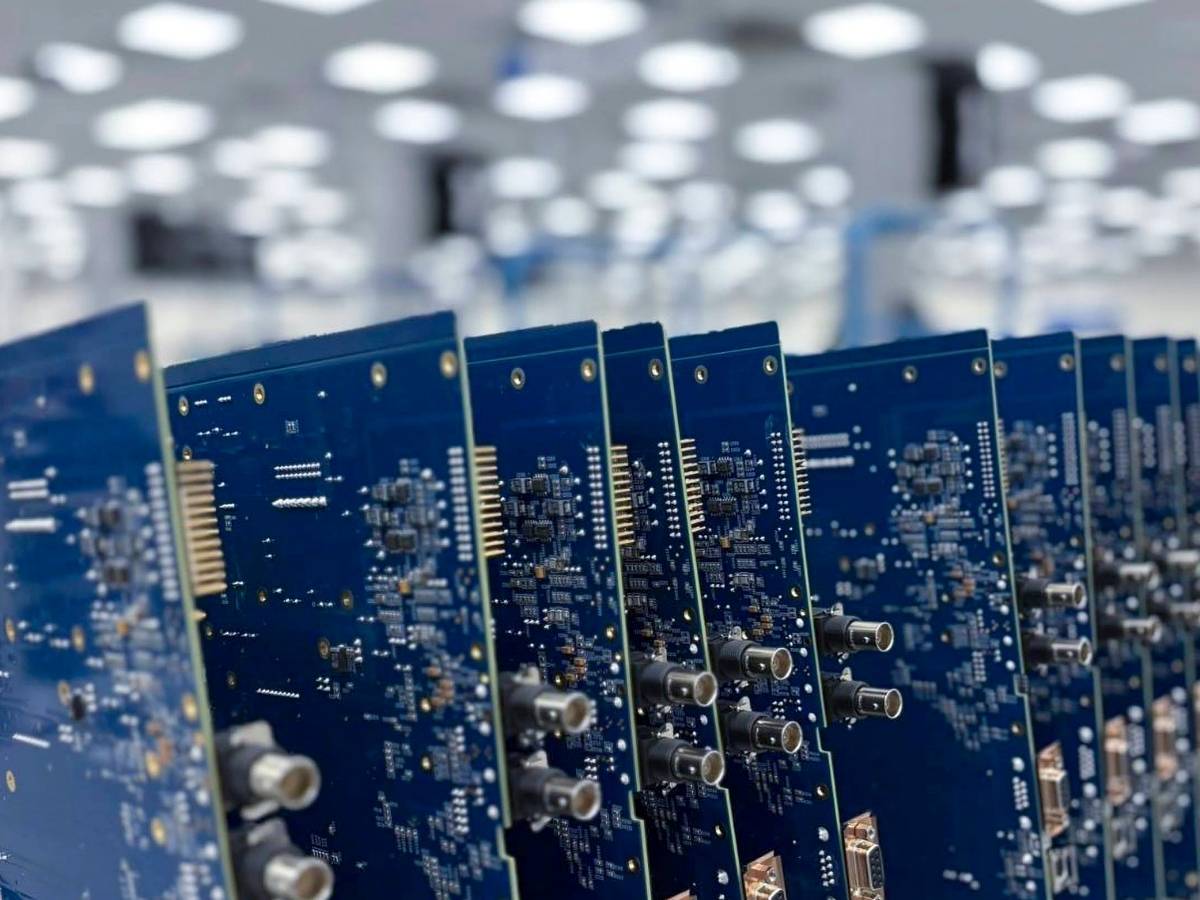

How ERP and MES transformed Incap Slovakia’s operations

Incap Slovakia, part of the global EMS provider Incap Corporation, began its ERP upgrade journey in mid-2024. This wasn’t just a software switch. It was a full rethink of how the factory operates, manages materials, and serves its customers. The move to SAP Business One, implemented with Slovak partner Softip, replaced legacy systems with a unified ERP and MES platform designed to boost speed, transparency, and scalability.

We spoke with Miroslav Michalik, Managing Director of Incap Slovakia, about what drove the change, what the team learned during the transition, and how the new system is already changing the way they work.

What made an ERP upgrade necessary?

Our previous ERP (Enterprise Resource Planning) system simply wasn’t keeping up. It had limited flexibility, lacked local support, and couldn’t evolve with our growing operational needs. The timing made sense. We needed a platform that could support real-time visibility, better automation, and integration across functions.

We evaluated our options carefully. SAP B1 (SAP Business One) offered the best price-to-value ratio and, more importantly, came with a strong local partner in Softip who brought both expertise and proximity. In a fast-moving EMS environment, you can’t afford to be stuck with systems that cannot adapt. ERP is the backbone of manufacturing operations, and we needed one that could support growth.

What did the implementation process involve?

We kicked off the project in May 2024. The first phase focused on building the technical infrastructure and preparing a test environment. From there, we mapped and redefined our internal processes, especially around production, to align with the capabilities of SAP B1 and its integrated MES (Manufacturing Execution System).

Training played a major role. We ran hands-on workshops with the implementation team and held daily 90-minute review sessions to track progress and resolve issues in real time. Before go-live, we also conducted a full stock take and prepared our BOM (Bill of Materials) and process definitions for migration.

It wasn’t without challenges. Translating between internal terminology and ERP system logic caused some delays. And in trying to simplify the transfer of work-in-progress items, we made a decision that turned out to be more time-consuming in the long run. It was a learning experience, and one that is already helping us shape better decisions going forward.

What impact has the new system had so far?

The biggest improvement has been transparency. We now have real-time access to detailed operational data across departments. Reporting is faster and more flexible, and teams in finance, controlling, and beyond can generate custom reports without relying on external support. It also helps that the system is fully localized and backed by a local ERP partner with strong support.

On the factory floor, the MES integration has improved the accuracy and visibility of material status. Barcode scans now feed directly into MES, providing instant updates and covering approximately 90% of all operations. This has helped us tighten inventory control and production planning. We also introduced barcode-based warehouse management, which reduced manual errors and improved the speed and accuracy of storing and kitting.

How does the new system benefit your customers?

The biggest gains for customers come down to efficiency, flexibility, and agility. We can now streamline operations and offer stronger value through faster turnaround times and clearer data. It’s also easier to respond to specific requirements and explore different production scenarios when planning.

Because ERP and MES are integrated, we can adjust quickly to changes, whether it is a new product introduction or a shift in delivery schedules. This is not just an internal upgrade. It directly improves how we deliver on quality, timelines, and overall reliability.

How did the transition affect the team and the way they work together?

The transition required a period of adjustment. The first five months after going live were focused on breaking old routines and learning how to work with the updated tools. We are now in the fine-tuning phase, customizing reports, improving processes, and making better use of the platform’s full capabilities. Overall, the response has been positive. People recognize the value of having a reliable, scalable system that supports more efficient work.

It has also changed how teams collaborate. During implementation, departments had to map and define their processes together in much more detail than before. Now that everything runs through a unified ERP and MES environment, working across functions is no longer optional. It is simply how the system works.

What are your next steps in digital development?

We’re currently working on upgrading our attendance system to give employees real-time access to their working time data. We’re also expanding our payroll system with HR modules to manage documents and processes more digitally. On the customer-facing side, we’ve already rolled out CalcuQuote for sourcing and are now implementing PipeDrive as our CRM. These tools will strengthen the entire customer journey, from first contact through to final delivery.

With SAP B1 now live, Incap Slovakia has laid the groundwork for faster, smarter, and more scalable operations. The shift is already making an impact across teams and strengthens their position as a trusted EMS partner ready to move at the pace of its customers.