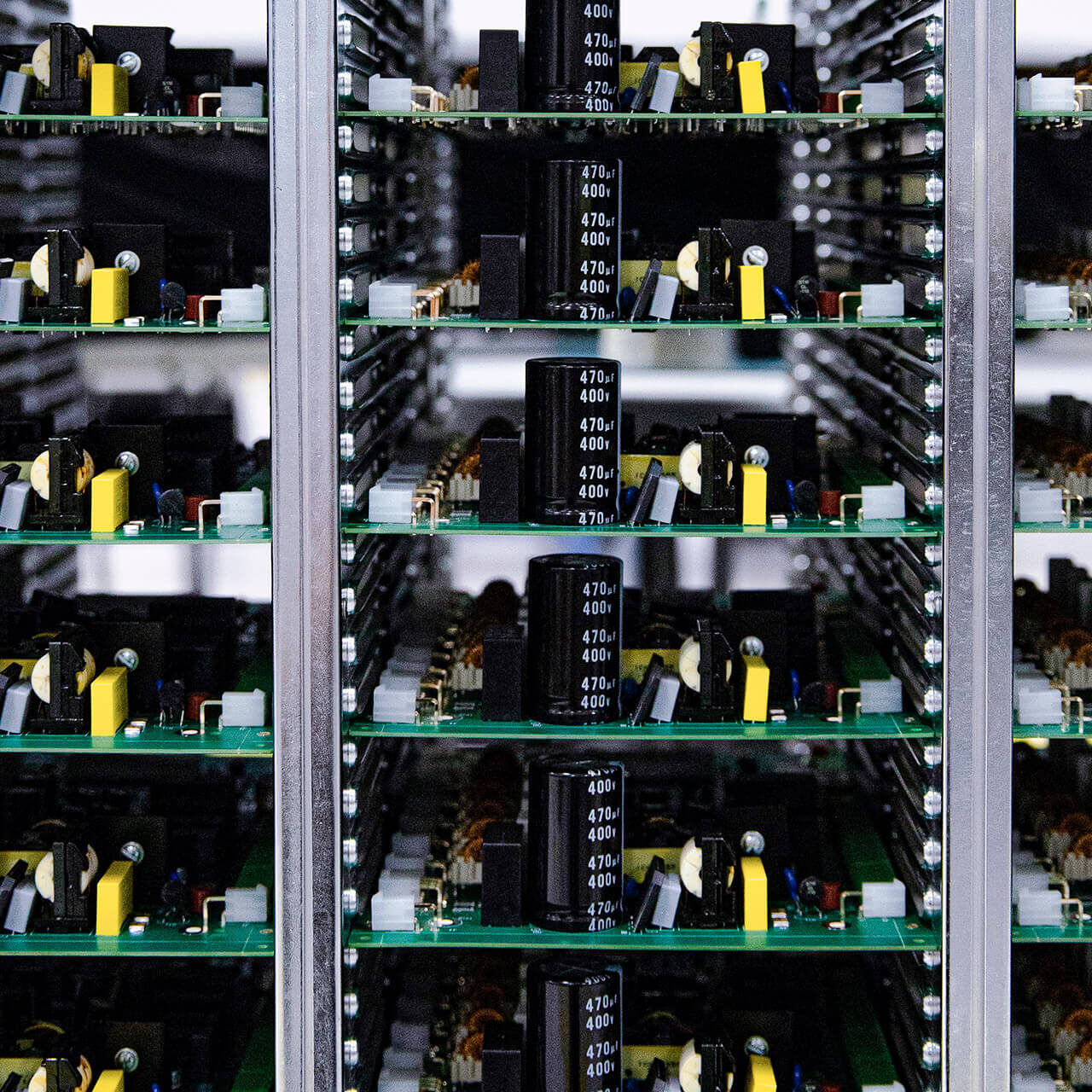

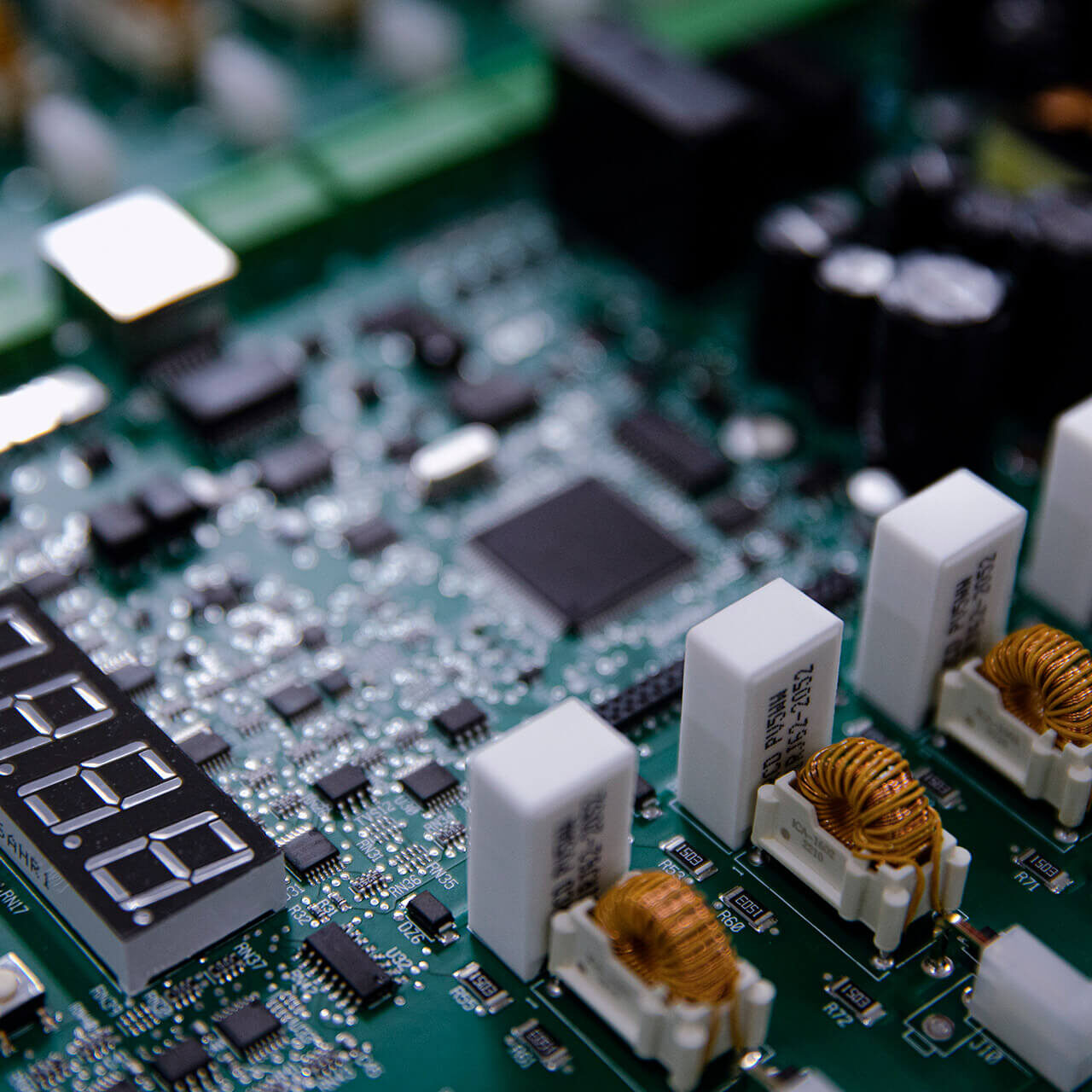

At Incap Electronics US, we take great pride in our achievements as a customer-focused Electronics Manufacturing Services provider. Our 6,500-square-meter manufacturing facility is state-of-the-art in every respect. Every project is driven by efficient, rapid-response methodology, stringent quality control, and highly skilled personnel. We deliver exceptional service, including customer design support, board assembly, testing, and box build – all at competitive pricing.

Our services benefit both high-mix, low-volume OEMs and low-mix, high-volume OEMs. We specialize in complex builds and tight turnarounds, and our size and flexibility enable us to custom-tailor our facility and staff to meet your biggest demands. We like to think of our services as an extension of your manufacturing capabilities, so when you choose Incap, you can count on a partner that’s focused on your goals.