Environmental responsibility

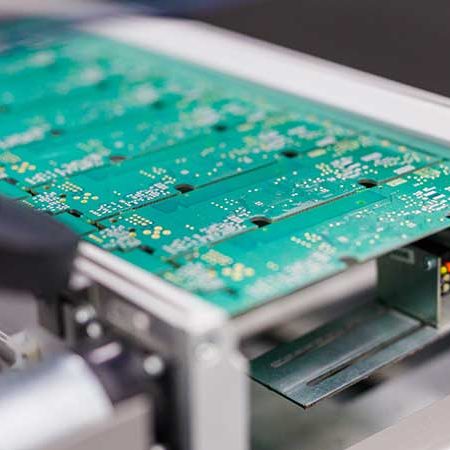

Incap is a contract manufacturer, so our customers choose the raw materials, materials and components used in our manufacturing processes. As a result, the environmental performance of our operations is strongly linked to our customers’ environmental objectives.

Incap has implemented an environmental management system (EMS) certified in accordance with ISO 14001 requirements almost in all its units. Incap also complies with all relevant laws and requirements to prevent pollution and reduce the consumption of natural resources and materials. No violations of environmental laws or regulations were found in Incap’s operations during 2024.

The majority of Incap’s energy consumption goes into heating, cooling and lighting of production facilities and for the operation of production machinery. Efforts to reduce energy consumption include the use of modern technology and energy-efficient equipment, led lighting, intelligent material flows and logistics.

Incap’s carbon dioxide emissions are generated by the energy consumption of its production facilities and by logistics, business travel, and purchased equipment and services.

To ensure efficient use of resources and minimise the amount of waste, Incap optimises the use of all raw materials in its production process. The focus is on improving recycling rates and waste management, which can be achieved by reducing waste of raw materials and line rejections.

The focus is on improving recycling rates and waste management, which can be achieved by reducing waste of raw materials and line rejections. We are also constantly striving to reduce the amount of hazardous substances in our production processes. To minimise the risks associated with hazardous materials and substances, we train our personnel and organise exercises to raise awareness and support their understanding of proper handling of hazardous materials, whether in day-to-day work or in the event of an accident.

These standards demonstrate our ability to consistently provide products and services that meet customer and regulatory requirements. By adhering to Incap’s Code of Conduct and Quality Guidelines and our Quality Manual, we also strive to continuously develop our processes, from design and raw material sourcing to production and distribution, to meet the environmental requirements of the customers whose products we design and manufacture.