Incap US welcomes Spider dispensing machine

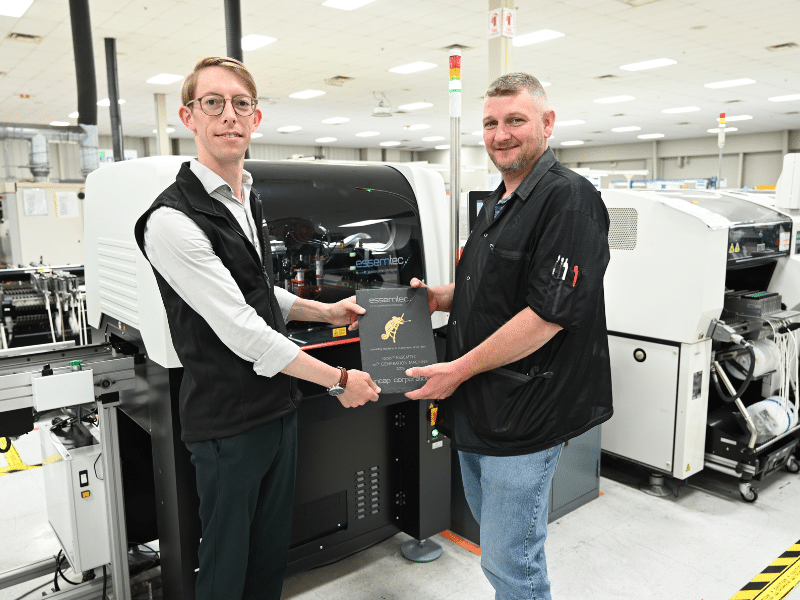

Incap US is pleased to announce the addition of the 1000th Spider dispensing machine from Essemtec, marking a significant advancement in Incap US’s electronics manufacturing capabilities. This new equipment aligns with Incap’s commitment to innovation, quality, and customer satisfaction in the EMS industry.

We are proud to partner with Essemtec, a leader in adaptive SMT pick-and-place and dispensing technology. The Spider system, now the 1000th unit of their latest generation delivered by Essemtec, represents the latest in precision dispensing technology.

The Spider system is known for its advanced features designed to meet the evolving demands of electronics manufacturing. Key attributes include:

- Multiple dispensing valves: With five different dispensing valves and quick-change capability, the Spider can manage two processes simultaneously, including jetting both SMT adhesives and solder paste down to the smallest 008004 pad sizes.

- High-speed dispensing: Offers speed and accuracy essential for maintaining high productivity and quality.

- Versatility: Capable of jet dispensing solder paste, surface mount adhesive, gel flux, and other mediums, the Spider provides the flexibility needed for diverse applications.

“We value our partnership with Essemtec for our dispensing needs,” said Don Ingold, Process Engineering Manager at Incap US. “The Spider system’s advanced capabilities align perfectly with our commitment to delivering top-tier solutions to our customers.”

The addition of the Spider system represents a strategic investment for Incap US. This machine will significantly enhance Incap US’s flexibility, enabling it to explore new projects and improve production efficiency. With features like high-speed jet dispensing and the ability to handle multiple mediums, the Spider will be instrumental in optimising production processes.

Incap US also opted for several additional features to maximise the Spider’s potential, including:

- ePlace software: Simplifies the creation of new profiles.

- Gerber file import and conversion: Expands options for creating new profiles.

- Integrated inspection system software: Ensures quality and process improvements remain on track.

As the Spider integrates into our production line, we anticipate numerous benefits, from reduced cycle times to enhanced flexibility in handling various projects. This strategic investment underscores our commitment to providing the highest quality services to our customers.