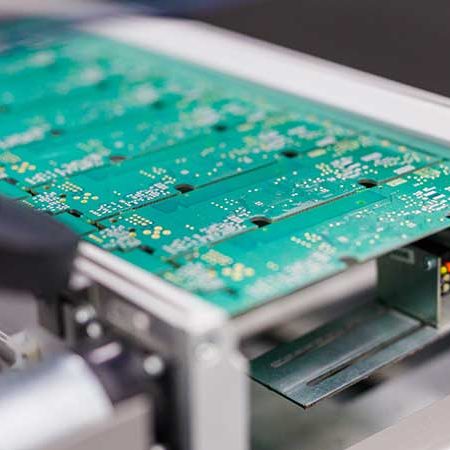

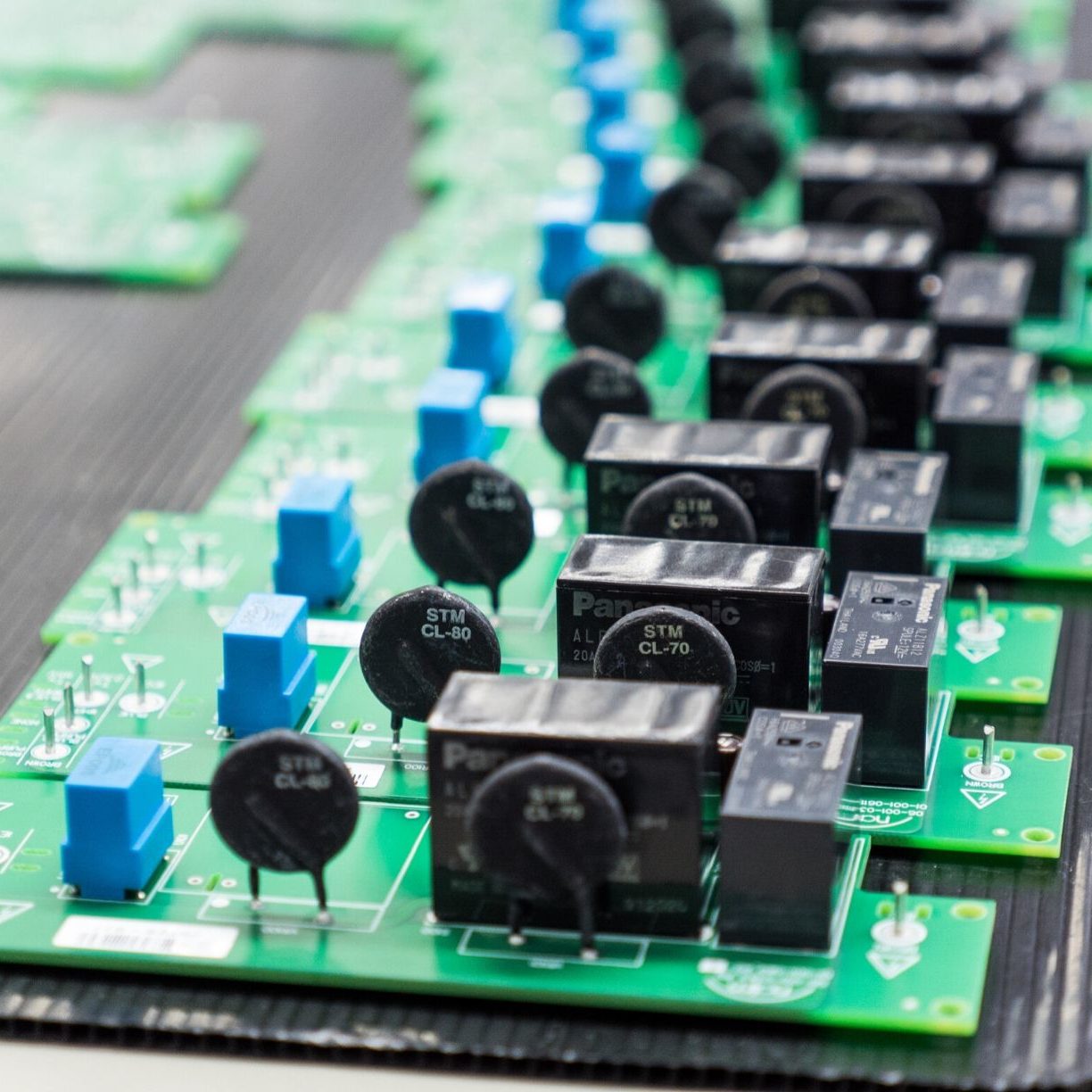

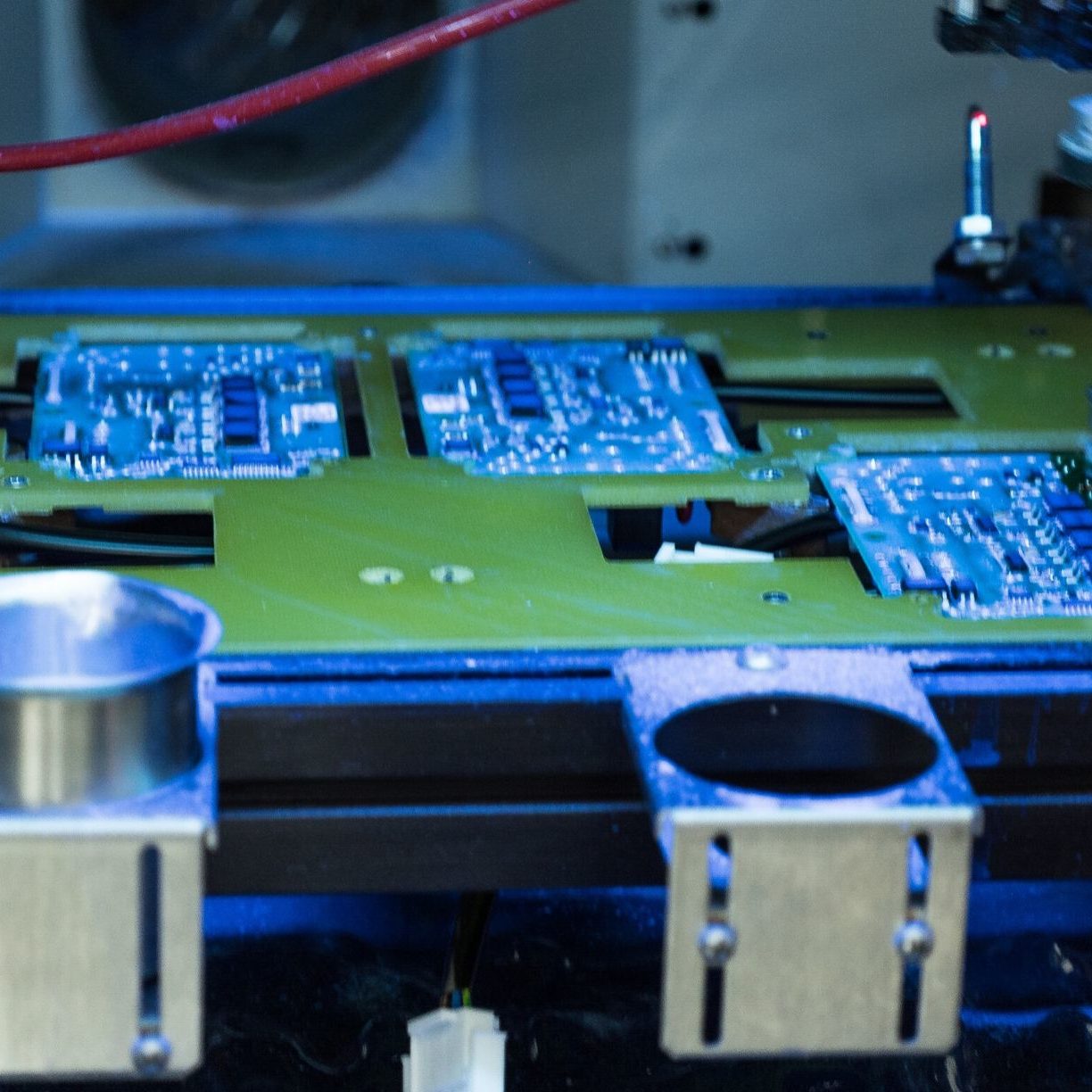

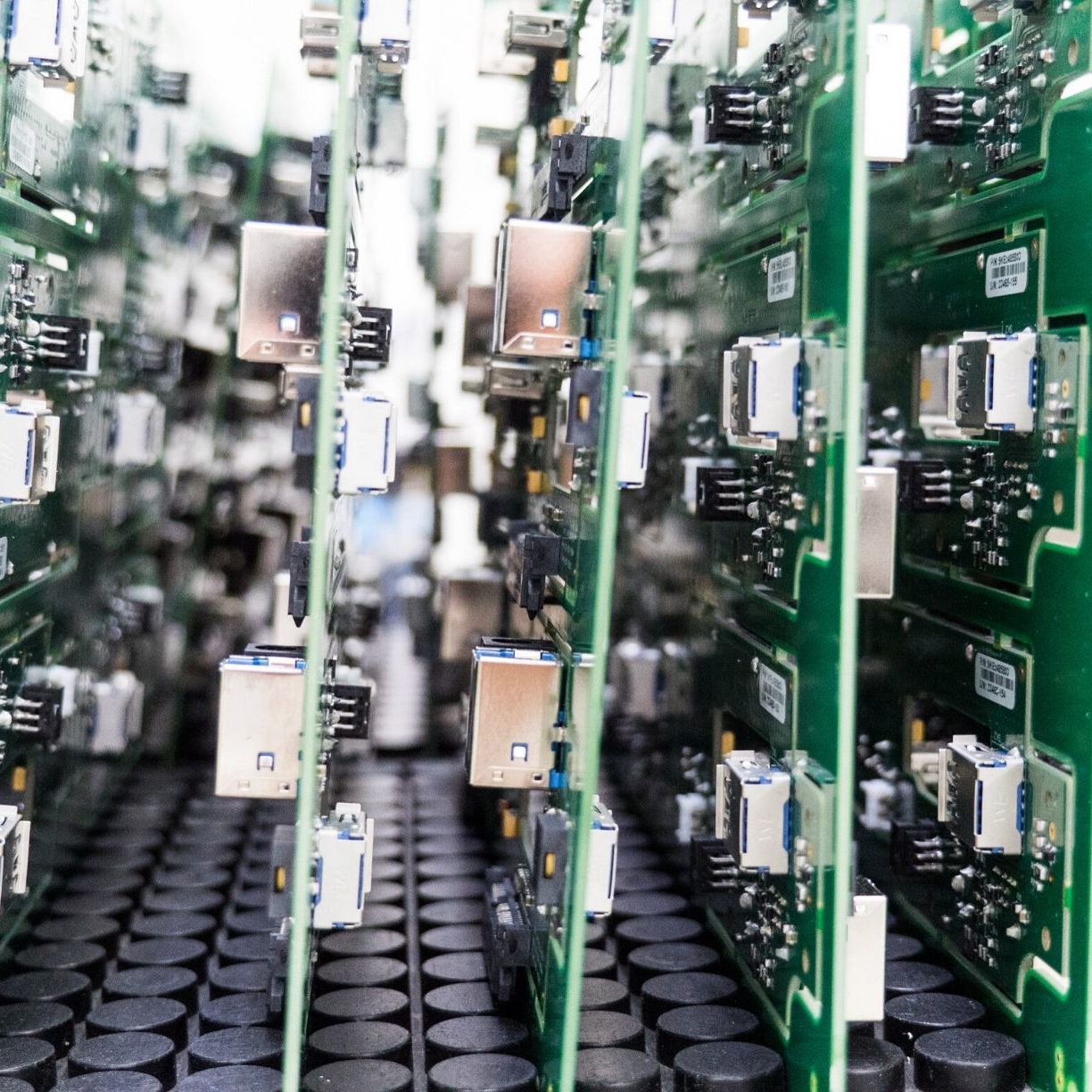

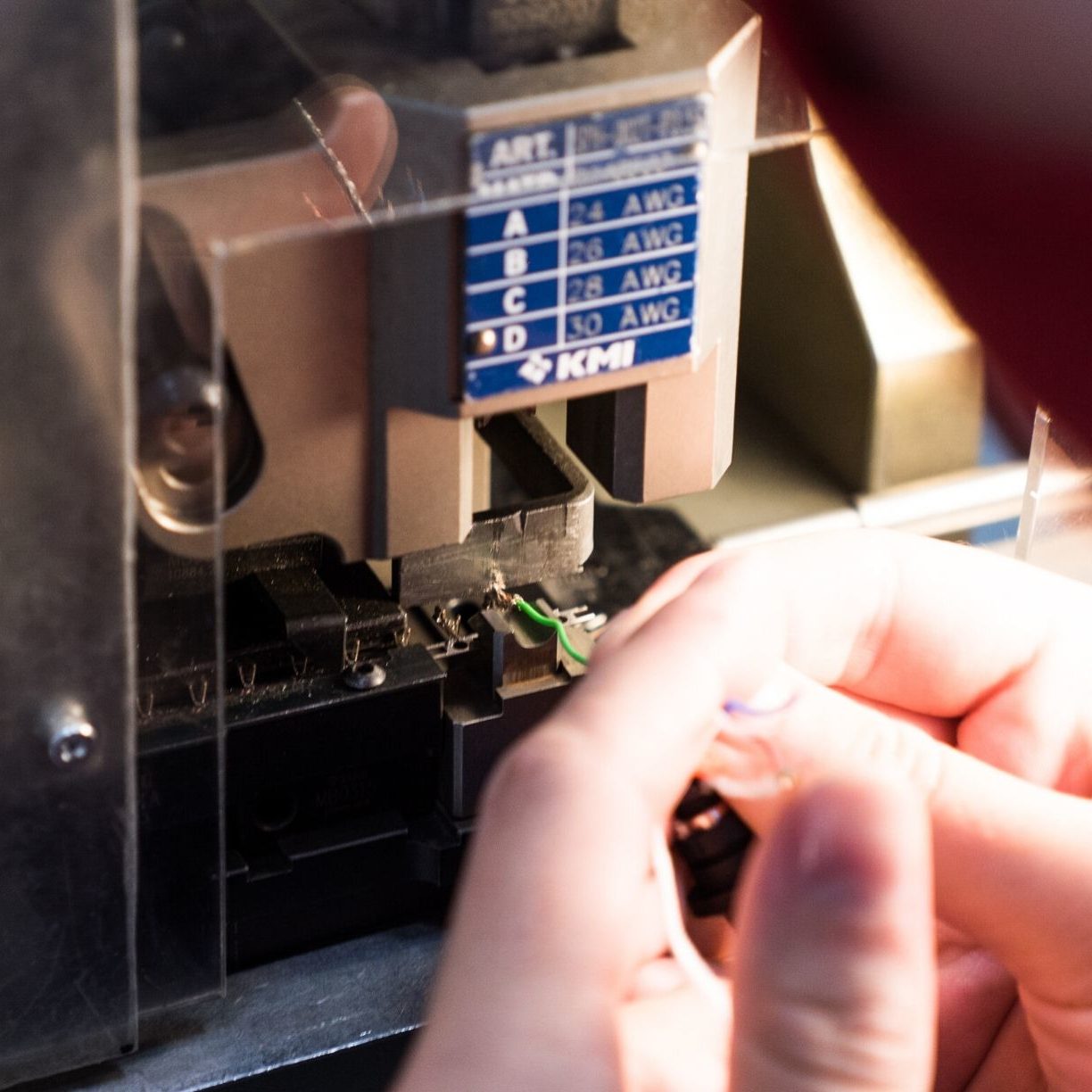

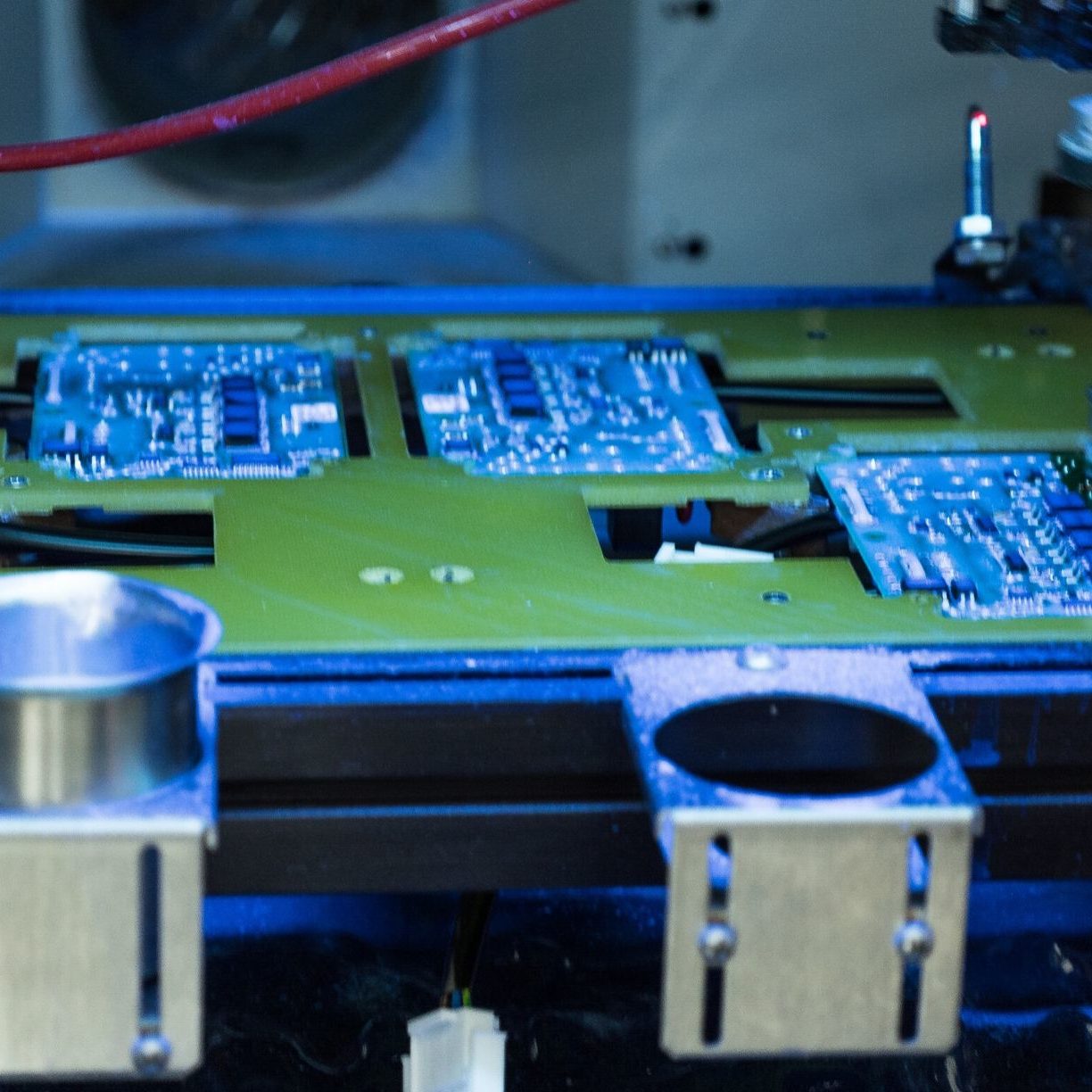

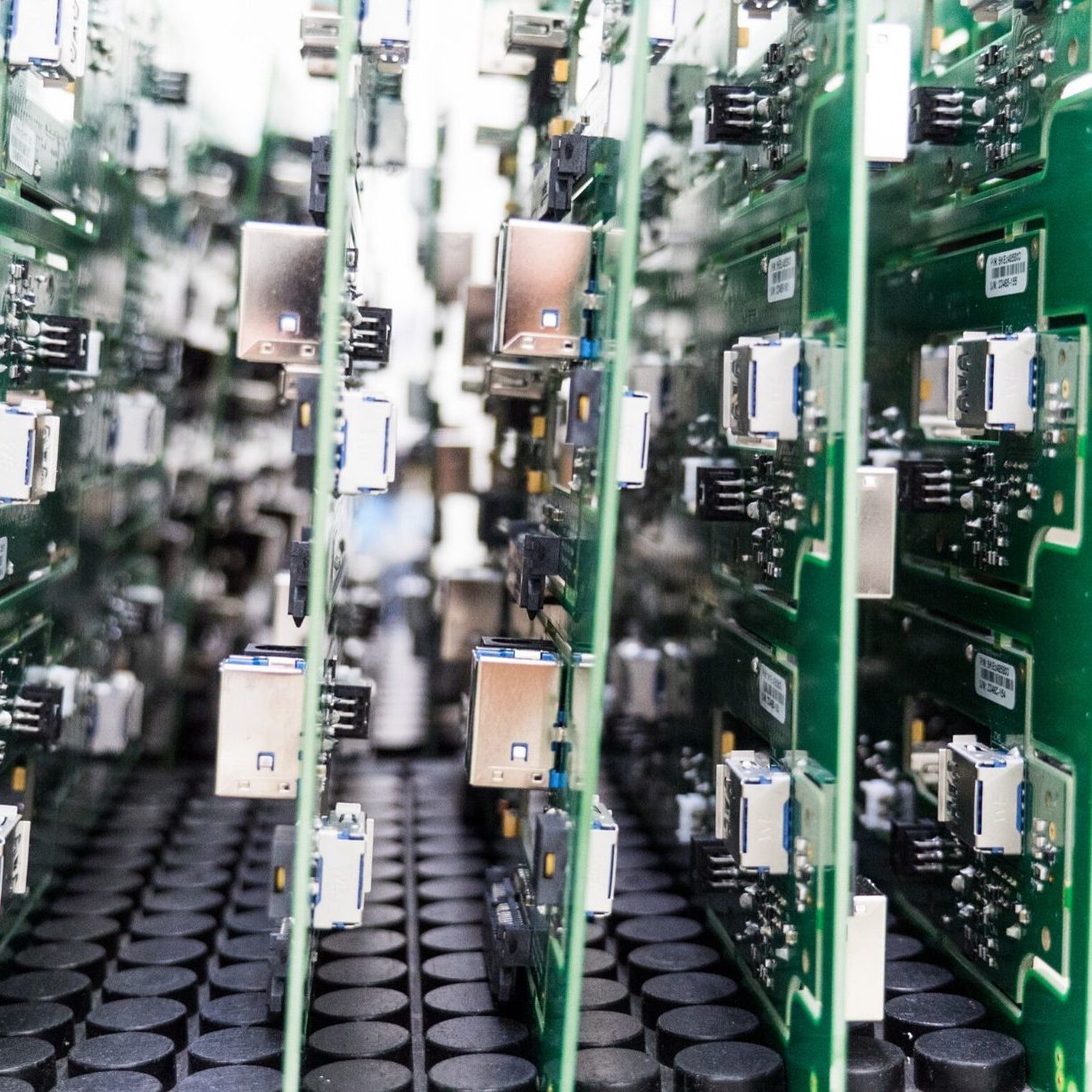

Incap’s factory in the UK, based in Newcastle-under-Lyme, provides full turn-key product supply including PCBAs, electro-mechanical assembly, cable and wire harness assembly alongside a dedicated standalone rapid prototyping facility (Fast Track), and maintenance, repair, and overhaul services (MRO).

Incap’s factory in the UK has experience in manufacturing since 1974. The factory has 4,400 square meters of total floor space. Its customers include global companies with operations in Europe, Asia, and North America. The facility also has over 20 years of experience in the defence, security, and aerospace markets.